Project Description

ONE CLAMP HOTMELT PERFECT BINDER – EB300H

Smart machine, big performance!

The Italian solution Ideal for great results with a small expense.

EUROBIND EB300H is a professional one clamp Perfect Binder with a roller sealing system, extremely compact ideal for small and medium production.

A perfect solution for a “On Demand” production.

Professional Perfect Binder, Brossuratrice professionale durable, reliable with minimal maintenance and easy service.

Automatic format change only set by entering the spine of the book block, this machine ensures high product quality in a short time and with low production costs at a speed of about 300 cycles / h

SPINE GLUING

The spine gluing system is made with two rolls immersed in a Hotmelt glue tank to ensure a better application of the layer of glue by guaranteeing a professional binding and a finishing quality product.

SIDE GLUING

The side gluing is applied by two discs, immersed in the same Hot-melt glue tank, that slip/crawl for direct contact at the sides of the book block, applying a thin line of glue to help cover holding along the scoring line.

TECHNICAL DATA

Production Speed

Book support board

Jogging: Motorized Jogging Sheet System (Optional)

HOTMELT TANK

Number of spreading rollers: 2

Side gluing: with disks

Opening / closing adjustment of glue disks: Automatic electric

Setting function: Start – Stop glue

THE SPINE

Pneumatic adjustment

Setting spine pression

Automatic setting of the spine thickness

Automatic control of the cover presence

Adjustment pressure time set by touch screen

DISPLAY TOUCH SCREEN

Color Touch-screen

Italian language and English, fast learning with simple symbolism and step-by-step guide to machine operation sets

Many features available like:

Pre-ignition time

Copy counter

Faulty and alarm signaling

Adjustment of glue line

OPTIONALS

- Motorized sheet smoothing system

- Height-adjustable leaf plate

- Mechanical milling tilt away

- Additional notchings

- Automatic height-adjustable press unit

- Automatic height-adjustable of the cover

- Kit for support plane of the cover

- Air compressor

- Hotmelt smoke/fume extractor

- Pre-ignition (to reduce waiting time)

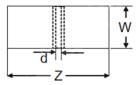

COVER SIZES

Lenght Z : max. standard 690 mm – 27.16 inch

Lenght Z : min. 290 mm – 11.42 inch

Height : max. 440 mm – 17.32 inch

Height : min. 140 mm – 5.51 inch

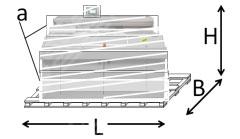

BOOK SIZES

Lenght b : max. 440 mm – 17.32 inch

Lenght b : min. 120 mm – 4.72 inch

Height h : max. standard 320 – 12.59 inch

Height h : min. 120 mm – 4.72 inch

Thickness d : max. 50 mm – 1.97 inch

Thickness d : min. 2 mm – 0.08 inch

Compressed air:

Static working pressure: 7 bar

Diameter of the compressed air inlet: Ø 8 mm

Max consumption of compressed air: 6 Nl/min

The compressed air supplied should be as dry as possible and free from oil and impurities

INTEGRATED ELECTRICAL CABINET

- Electrical specs : 400V ± 5%, 50Hz, 3PH+N + PE / 13A 6,5 KW

- Compressed air, static working pressure: 7 bar

- Diameter of the compressed air inlet: Ø 8 mm –

- Consuption : 6 Nl/min

- The compressed air supplied should be as dry as possible and free from oil and impurities.

WEIGHT AND DIMENSIONS OF THE MACHINE

Lenght : 1680 mm – 66.14 inch

Width : 670 mm – 26.38 inch

Height : 1400 mm – 55.12 inch

Weight : c.a. 300 Kg – 661.38 lb